Presentation of the ingot production process by NorSun

Presentation of NorSun and its role in ICARUS

NorSun is a Norwegian solar energy company that manufactures and markets high performance mono-crystalline silicon ingots and wafers for the global solar energy industry. Dedicated to high efficiency n-type wafers and sustainable production with low CO2 emissions, we are an established supplier to tier-one cell manufacturers. NorSun operates a modern production facility located in Årdal in western Norway, pursuing a detailed and aggressive technology development and cost road map which ensures a competitive price model. The NorSun plant is powered by low cost renewable hydropower, enabling very low emissions from production.

NorSun’s mission is to be a leading manufacturer of silicon ingots and wafers for premier solar cells, through innovative technology, sustainable production and operational excellence.

In the ICARUS project, NorSun collects and supplies used graphite parts, quartz crucibles, kerf loss and coolants to the project partners for their recycling developments. Furthermore, NorSun is developing and testing a method for pot-scrap suction in order to remove low-quality molten metal from the crucible and thereby extend crucible life and improve productivity.

Presentation of the ingot production process

Description of the process

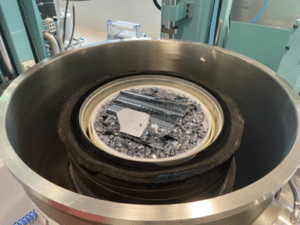

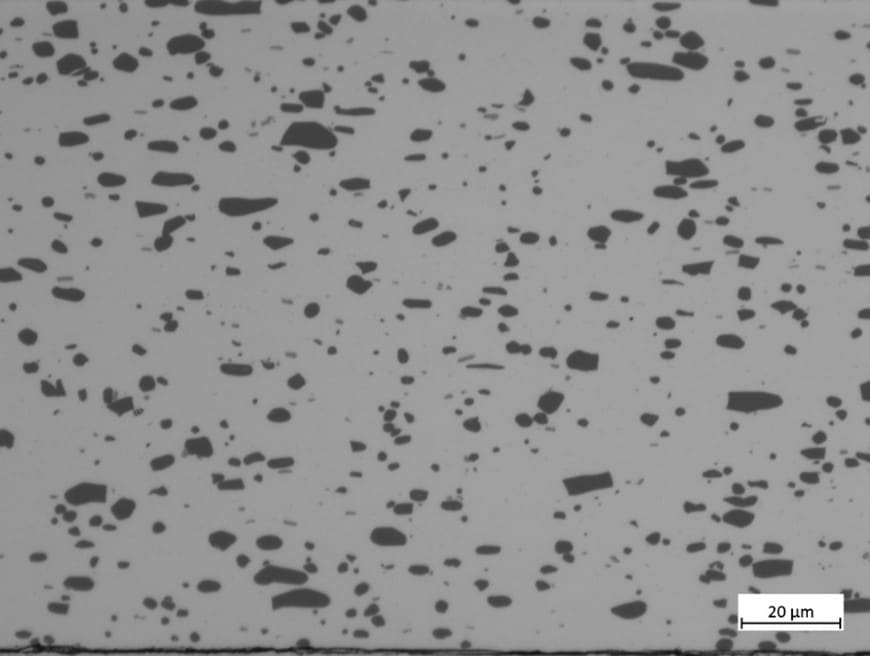

Monocrystalline ingots are produced by the Czochralski process. The process starts by putting a quartz crucible filled with solid silicon inside a furnace chamber mostly made from graphite.

Quartz crucible with solid silicon ready for melting

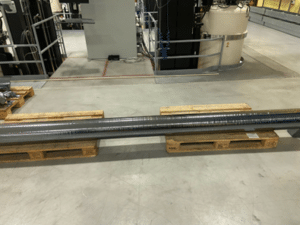

Finished ingot

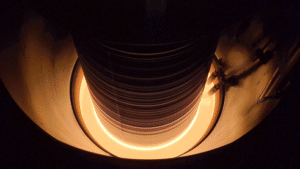

The silicon is melted at 1410°C in vacuum and argon and further solid silicon is added. Next, a seed crystal is dipped into the melt and rotated. The ingot is produced by slowly lifting the seed with the growing crystal from the melt, and the diameter can be adjusted by adjusting the rotation speed and lifting speed. The pulling speed is very slow in order to maintain only one single crystal in the full ingot. The cylindrical ingots produced are 228 mm diameter, 3.5 meter long and weigh 360 kilograms. After crystal pulling the ingots are taken through a sawing process to produce wafers with a thickness of 150 μm (similar to the thickness of a human hair) for production of solar cells.

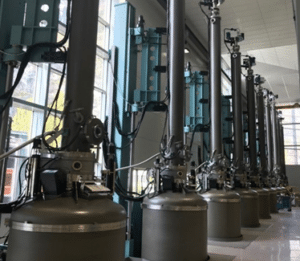

Image of pullers

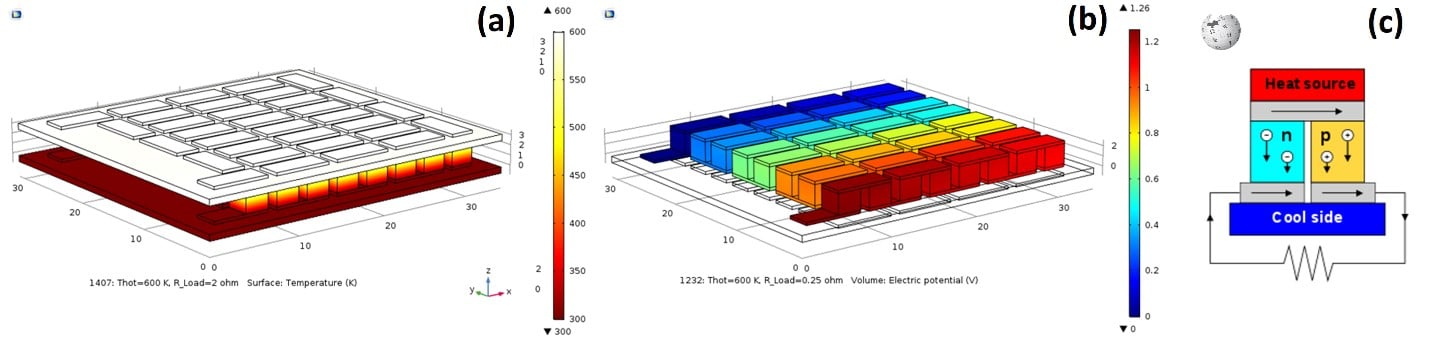

Illustration of the pulling process

Main challenges related to the ingot production

The main challenge is the pot-scrap suction. In the ingot production process, large monocrystalline crystals are pulled from the melt. Inherent in the solidification process is that the impurities are enriched in the remaining liquid. After pulling two or more ingots, the melt therefore contains relatively high levels of impurities. It is therefore valuable to have a method to remove this ‘waste’ material and replace it with virgin polysilicon to obtain high quality ingots, increase productivity and extend crucible life. A pot-scrap suction device will be developed and tested in the project. This is quite challenging as it requires a solution that can sustain the vacuum, reactivity of silicon and high temperatures involved without creating any production problems. Furthermore, the melt level will be quite low when the pot-scrap is removed which requires careful control to obtain an efficient removal.

ICARUS first results

No result yet since the tests have not started.

Next steps

The next article written by NorSun will present the wafer sawing process and the collection of saw dust.