Today’s challenge

A common feature of photovoltaics, microelectronics and sensors is their outstanding growth perspective, Europe having strong ambitions for them, and they all rely on a critical upstream process: the transformation of silicon metal (a critical raw material) into wafers.

All the downstream value chains depend on this CRM. Taking the PV industry as an example, each € created in the upstream industry creates 2.7€ in the downstream value chains. It is of utmost importance to make this upstream value chain safe and efficient.

The process turning Si into wafers is very energy intensive (about 80 MWh/t) and generates large waste streams. Upstream processing of silicon to wafers supports several important European industries that currently rely so far mostly on Asian supply, which is a major risk largely understood these last months with the current COVID-19 pandemics.

ICARUS will secure this process to foster European growth on downstream value chains. This will be done by turning the upstream process wastes, rich in highly pure Si and energy-dense, into a secondary raw material.

of Icarus consortium

Enable the recovery of >95%

of high value material from ingots and wafers manufacturing

Scale-up modular solutions

to process, recycle and refine Si-kerf, and alternatively transform Si-kerf into valuable raw materials

Develop industrial symbiosis

by providing processed and refined material to further high-end applications

Ensure the actual implementation

of the project’s outcomes in the real world

ICARUS will be a driver for a new start of the European PV industry

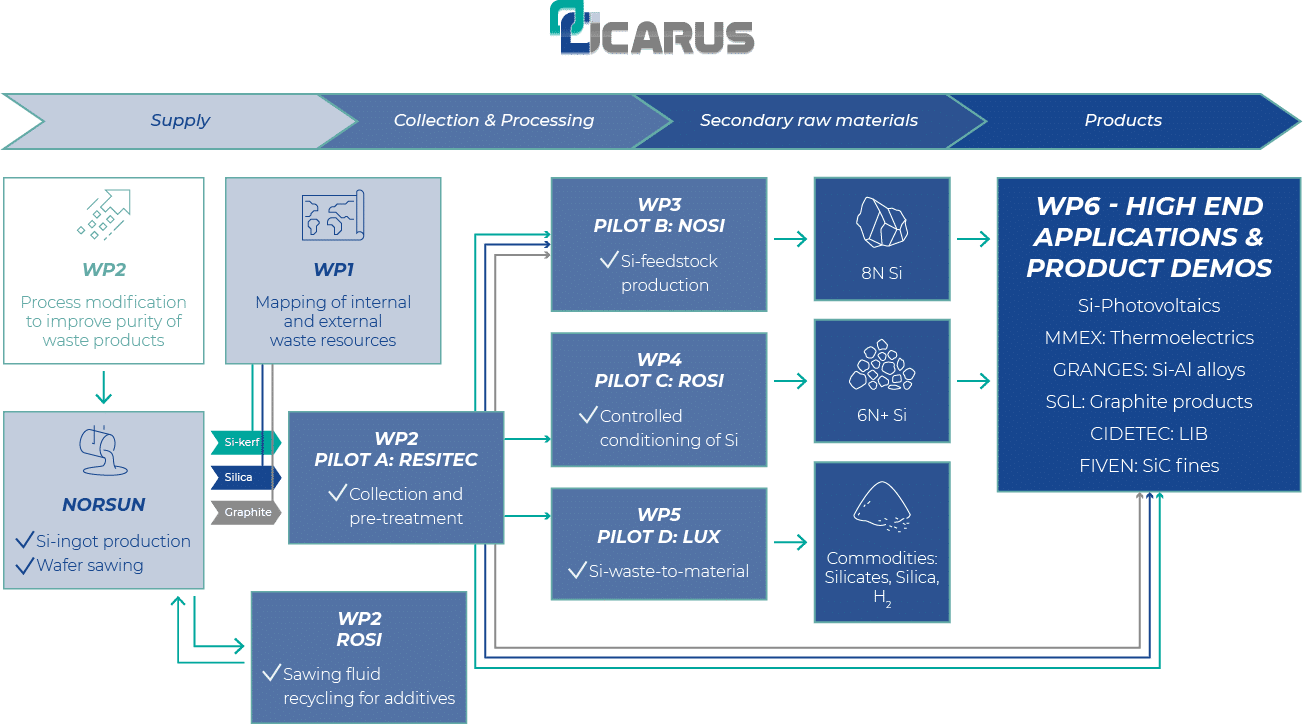

ICARUS will demonstrate :

3 innovative industrial pilots producing silicon, silica and graphite raw materials :

- Pretreated and purified silicon, silica and graphite raw materials (RESITEC)

- Pyrometallurgical process using recycled silicon, silica and graphite for high purity silicon (NOSI)

- Granular silicon feedstock for photovoltaic applications (ROSI)

1 pilot converting silicon waste into full value industrial commodities :

- Full value industrial commodities: green hydrogen, silica and silicates (LUX), for different high-end applications with strict raw material quality standards, to assess the technical and economic viability of these applications :

- Si-photovoltaics (CEA)

- Al-Si alloys (GRANGES)

- Thermoelectric modules and generators (MMEX)

- Lithium ion battery cells (CIDETEC)

- Silicon carbide powders (FIVEN)

- Fine-grained graphite (SGL)