Presentation of the use of recycled Si-kerf in aluminium alloy production in line with Gränges’ strategy for sustainable growth

Presentation of Gränges and its role in ICARUS

With a 128-year history, Gränges is a customer-driven, world-leading rolling and recycling aluminium company with a very strong Research & Innovation. Gränges, currently around 2700 employees, has operations in Sweden, Poland, France, China and the US, delivering products into various application areas, including automotives, HVAC, and niche markets. Gränges, as a global leader, specializes in producing rolled aluminium products for brazed heat exchangers to the automotive industry with a global market share of approximately 20 percent. Every second car manufactured worldwide today incorporates materials from Gränges.

Gränges has always been committed to develop sustainable aluminium products and engage in creating circular solutions to minimise the environmental impacts of operations. Today, there is a significant trend towards increasing the use of recycled aluminium scrap both from industrial process and the use of the end-of-life scrap from consumers to improve energy efficiency and reduce emissions and carbon footprint. “Gränges Endure” is a newly launched product brand for sustainably sourced and produced.

Figure 1 : “Gränges Endure”

Gränges Finspång, in Sweden as an aluminium producer participates in the ICARUS-project. A pilot-scale demonstration will be done at Gränges to produce Al-Si alloys using Si-kerf recovered from photovoltaic wafer manufacturing processes and adapting the best practices based on lab-scale, alloying & process techniques and conditions.

Presentation of Al-Si alloying and microstructure modification

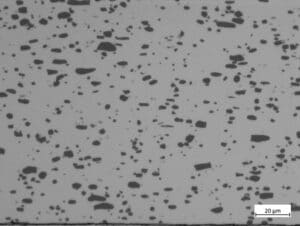

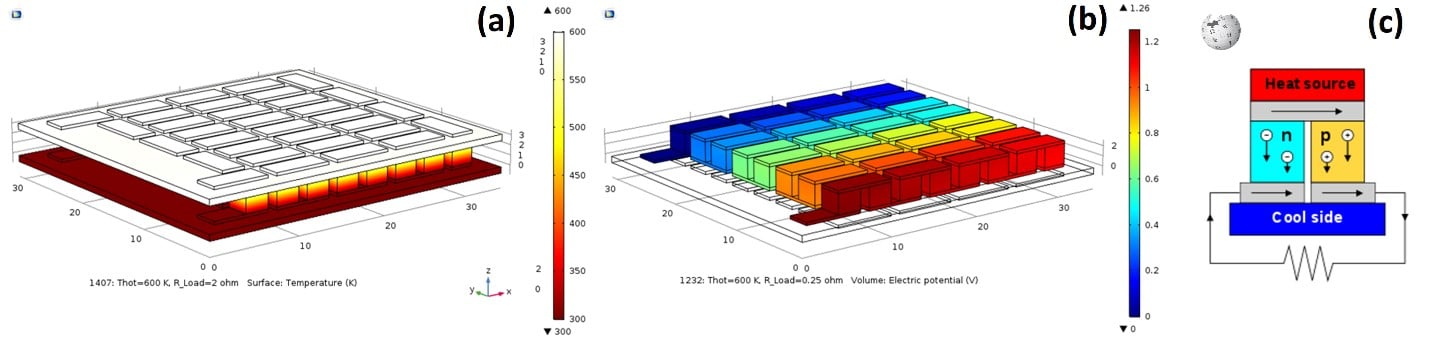

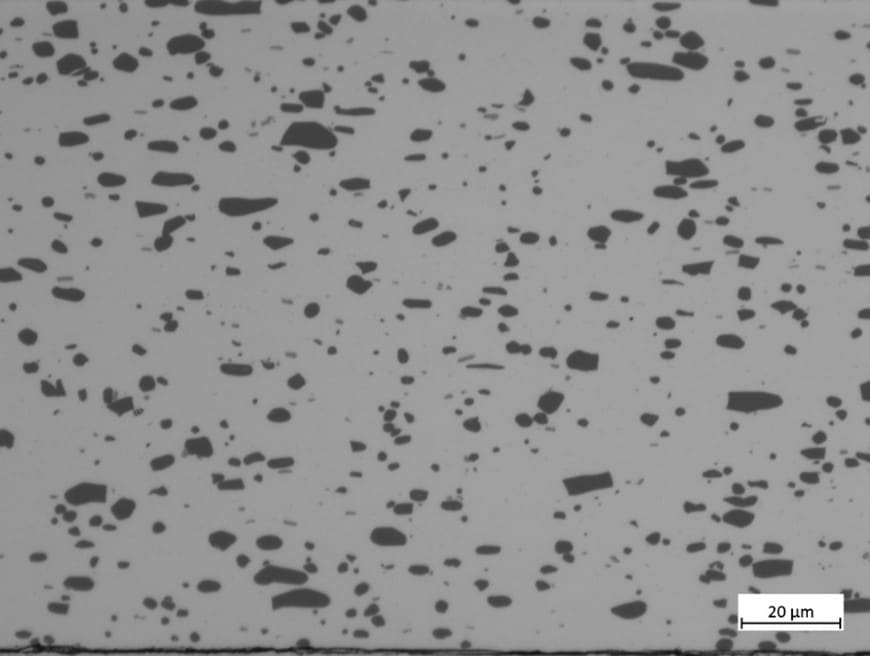

The Al-Si alloys are used as filler metal in brazed heat exchanger applications due to their relatively lower melting point compared to the core/base alloys. However, Si-growth emerges as a predominant phase in the eutectic formation during casting, yielding large primary Si-particles in the microstructure. This can lead to core alloy erosion issues during brazing, affecting the overall performance and longevity of heat exchangers. Small addition of strontium in the Al-Si alloying process has become a standard procedure at Gränges foundry to modify morphology of eutectic silicon from coarse flakes to small spherical or rod particles. This microstructural modification significantly improves the mechanical properties of Al-Si alloys and minimizes the tendence to material erosion afterwards in brazing.

Figure 2 : Si master alloy used for the alloying process.

Figure 3 : typical microstructure of AlSi braze alloys

In ICARUS project, the melting procedures are being developed to replace conventional silicon raw materials with recycled Si-kerf as an alloying element in the production of aluminium-silicon alloys. Replacing with the silicon-kerf goes hand in hand with Gränges’ strategy for sustainable growth. However, achieving mutual wetting and melting of aluminium and Si-kerf poses great challenges. The micro-sized Si-kerf particles are covered with an oxide layer that is difficult to break and dissolve, thereby hindering the melting process with aluminium. Exploring the potential use of recycled Si-kerf in the manufacture of Al-Si alloys with sustainable practice is essential for a more environmentally friendly and efficient future of heat exchanger technologies. This work is being done in collaboration between industries and academia, through optimizing the metallurgical melting process to ensure that the recycled Si-kerf can give a sustainable solution without compromising the quality of melting products.

ICARUS first results

The necessary Si quality for production of heat-exchanger materials has been specified. Expertise and knowledge on “industrial alloying process techniques” were shared among ICARUS-partners. Optimization of the melting process is currently on going.

Next steps

Finding out the optimal metallurgical techniques to break/dissolve oxide layer on Si-kerf particles is clearly the key in overcoming the difficulties. The breakthrough would enable the start-up of the melting trial on industrial scale. In the next step we will focus on the industrial pilot scale demonstration of Al-Si alloy.