Presentation of pot scrap recycling by ReSiTec

Presentation of ReSiTec and its role in ICARUS

RESITEC AS is a Norwegian company, owned by Å Energy, that is specialized in the recycling of industrial waste and side stream materials, bringing them back to market and into a circular economy. Core activities comprise research and development of new processes and products, pilot testing and verification, engineering and recovery services/production. RESITEC is in addition a producer of recycled silicon powder (kerf) from the photovoltaic industry. Today the product mainly goes into lower end markets, but RESITEC is working on the development of the product towards higher end applications.

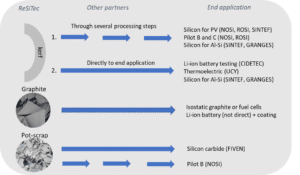

In ICARUS, RESITEC is responsible for work package 2: “Make the ingots manufacturing industry circular”, and task 3.1 “Upscaling and demonstration of economical method for raw materials purification and agglomeration pre-treatment“. The main activities are to develop processes and industrial scale demonstrators for the waste streams, silicon kerf, graphite and silicon, making them suitable for the different applications. This is Pilot A in the project. The materials processed by RESITEC are either going directly to the end applications or to one of the other pilots, see sketch below.

Presentation of pot scrap recycling

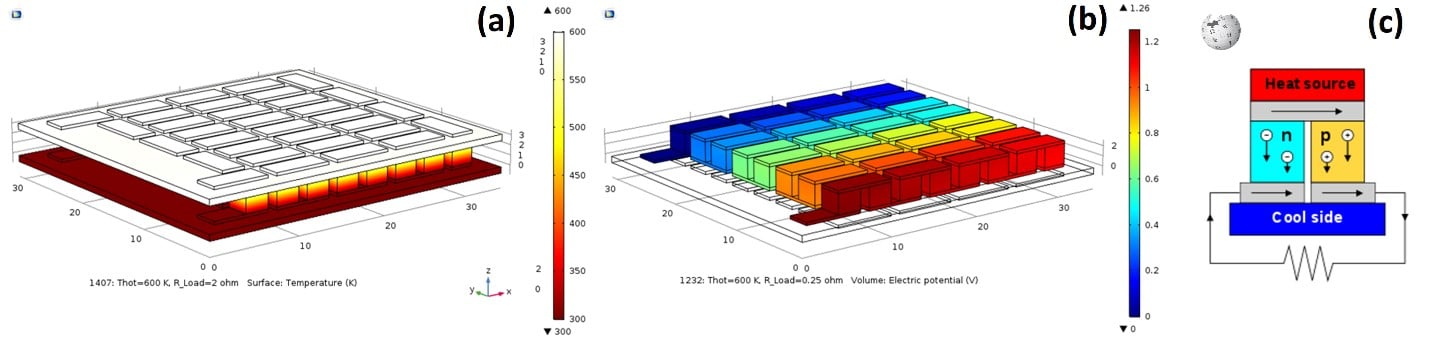

For the recycling of pot-scrap (silica) there are two applications considered in ICARUS:

- metallurgical silicon production (PILOT B)

- silicon carbide production

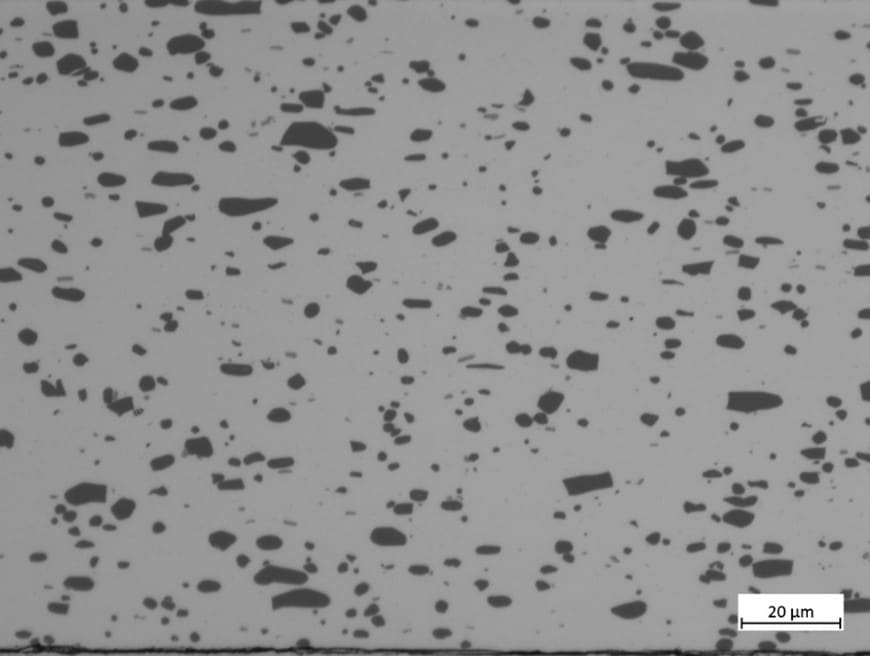

The requirements are different, as for the metallurgical silicon production the product can be subjected to further refining techniques which are often not applicable for silicon carbide products. Therefore, the chemical requirements for the feedstock (silica) going into the production of silicon carbide is particularly high, and this narrows further in if the end product is a high purity silicon carbide for the semiconductor industry. At the ingot producer, the silica crucibles with remaining silicon (pot-scrap) are wrecked after every furnace run, see image below. There is no sorting regime established and the material can contain remnants of graphite and carbon foil. The challenge for Pilot A has therefore been to establish a suitable processing route for the material, which results in a silica feedstock with the targeted size distribution and a high enough purity. Particularly, aluminum can be a challenging element due to fact that the crucibles in use may contain significant amounts of this element.

ICARUS first results

During the first period a pilot-scale processing route was established for the pot-scrap material, as well as a collection procedure at the ingot manufacturer. Several production campaigns have been run with the processing route established, and materials were delivered to both Pilot B and silicon carbide production. The results from Pilot B are not ready yet, but for the silicon carbide production two successful runs have been completed. The produced silicon carbide was in both runs of high purity grade, showing that this level of aluminum in the feedstock is acceptable.

Next steps

The results on the production of silicon carbide yielding a high purity product were very positive, and in the next phase we will do a third run with processed pot-scrap from the established route to see if the high yield and high purity can be reproduced. As a consequence of these positive results we will also look into the possibility of running a large production campaign within the project for demonstration in industrial scale silicon carbide production.