Presentation of High Purity Silicon Carbide production by FIVEN

Presentation of FIVEN and its role in the ICARUS project

Fiven is a worldwide leading producer of silicon carbide powders with production sites in both Europe and America and with a R&D team in Lillesand, Norway.

Due to a growing demand for high purity silicon carbide for the electronics and semiconductor industry, Fiven has developed a production route for high purity silicon carbide using the traditional Acheson process.

In the ICARUS project, Fiven will explore the possibilities of reusing waste silica-crucibles (“pot-scrap”) from the Photovoltaic (PV) industry to produce high purity silicon carbide for the electronics and semiconductor market.

High purity silicon carbide production: process and challenges

Fiven will demonstrate the substitution of quartz with pot-scrap to produce high purity silicon carbide. The pot-scrap originates from the production of silicon ingots and contains both silica and silicon of high purity. There will be several tests in a pilot Acheson furnace where pot-scrap is mixed with a carbon material and heated up to high temperature to produce silicon carbide crude.

Furthermore, the crude goes through several steps of refining before the high purity silicon carbide powder is ready. The success of the tests will be strongly dependent on both the yield and quality of produced silicon carbide.

One of the most difficult challenges in this project are related to the impurity levels of the pot-scrap and how it may vary over time. The electronics and semiconductor industry have strict requirements on the number of impurities in silicon carbide. In contrast to the predictability of geological quartz, pot-scrap will have a quality which is far more dependent on human factors. Hence, the pot-scrap is expected to have a high variability which we need to monitor and stabilize before it can be used to produce high purity silicon carbide.

ICARUS first results

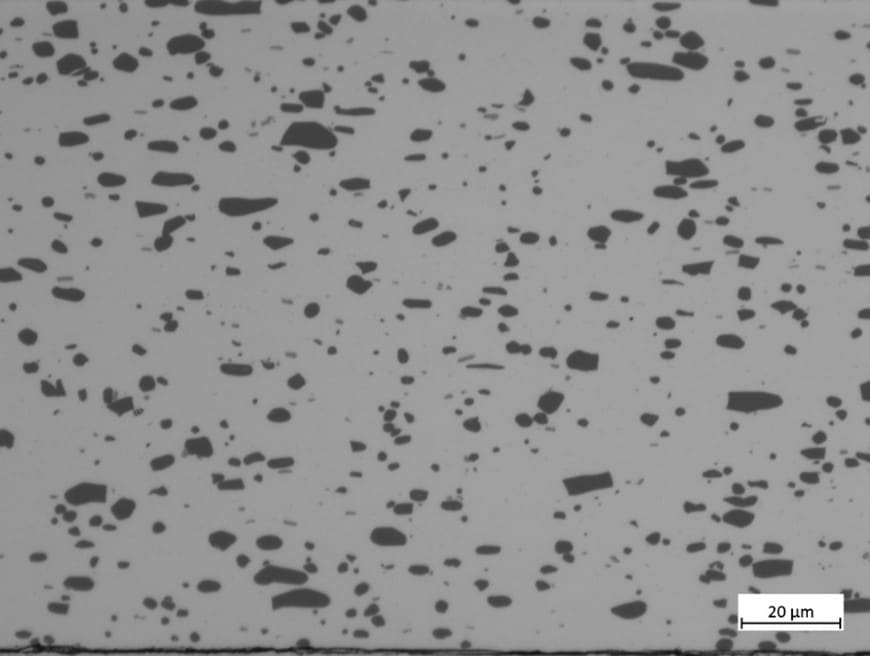

Several pilot furnaces have been run with pot-scrap and the results show a good yield and quality of silicon carbide product.

Image of high purity silicon carbide produced with pot-scrap.

Next steps

More tests will be performed in the pilot furnace to verify the reproducibility of these results.