Presentation of closing the loop of isostatic graphite by SGL Carbon

Presentation of SGL Carbon and its role in the ICARUS project

SGL Carbon is a technology-based company with around 4,700 employees and 29 production sites in Europe, North America, and Asia. With customers in more than 100 countries they generated a revenue of €1.1bn in 2022. SGL Carbon is one of the world’s leading manufacturers of carbon-based products. Their comprehensive portfolio ranges from carbon and graphite products to carbon fibers and composites. They focus on creating innovative solutions and value for their customers.

Multicrystalline and monocrystalline silicon are the most important raw materials for the production of solar cells in the photovoltaic industry. SGL Carbon supplies key components based on specialty graphite for their production. These include heaters, crucibles and heat shields made of high-purity fine grain graphite or carbon fiber-reinforced carbon, as well as insulation components made of graphite felts. During the ICARUS project, SGL Carbon is testing whether it is possible to close the loop for End-of-Life (EoL) isostatic graphite from the solar value chain.

Presentation of the use of graphite in the solar industry

Graphite in solar cell production

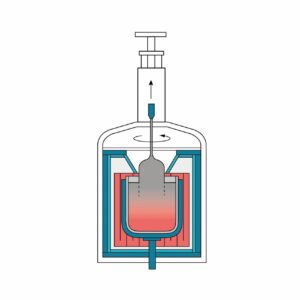

The best conversion efficiencies of sunlight into electricity of commercial solar cells can be obtained by monocrystalline based silicon solar cells. The silicon wafers are cut out of silicon ingots grown by the Czochralski (CZ) method.

The crystal growing furnaces used for this process operate at high temperatures of around 1,500°C and are equipped with an isostatic graphite hot zone, consisting of a heater, outer tubes and rings, a quartz crucible susceptor and, depending on the particular design, other graphite items.

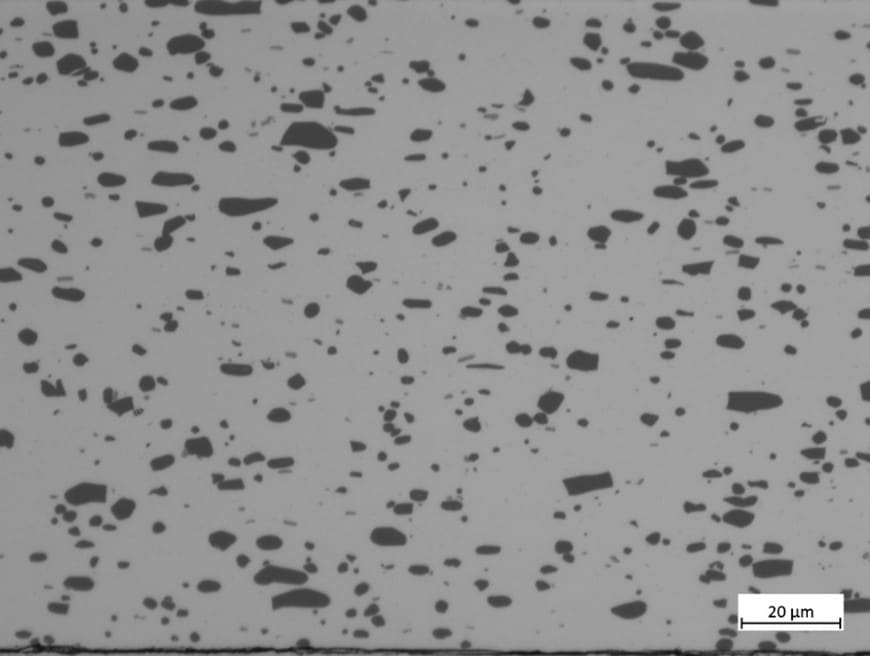

The term isostatic graphite stands for isostatically molded graphite. The raw material mixture is shaped using compression into rectangular or round blocks in a so called Cold-Isostatic-Press. Isostatic graphite, such as SIGRAFINE®, can provide high strength and homogeneity which make it interesting for some applications such as the production of silicon crystals and wafers in the solar industry.

Figure 1: Czochralski crystal growth reactor showing materials made from isostatic graphite and other carbon materials (Copyright SGL Carbon).

SGL Carbon produces and offers all the materials needed from one source and has decades of experience in finding the right solutions.

Production of fine grain isostatic graphite

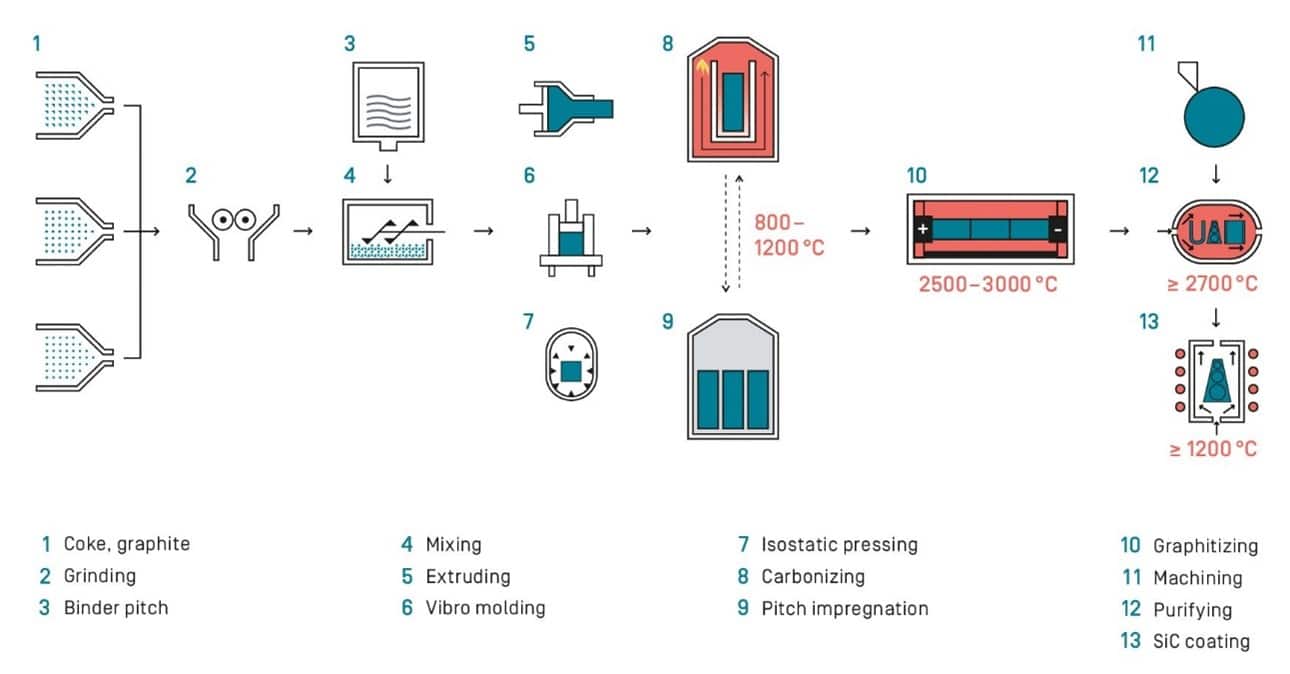

The production process for isostatic graphite which is also described on SIGRAFINE®, starts with the mixing of their raw materials coke, synthetic graphite, and pitch. The raw mass is then formed, carbonized at temperatures up to 1,200 °C and finally graphitized at temperatures up to 3,000 °C. The selection of raw materials in combination with proper processing is crucial to achieve the desired material properties such as « solar grade » purity (200 ppm or less), fitting thermal and electrical conductivity, or low thermal expansion. The material purity required for solar cell production can only be achieved by using raw materials that are already sufficiently pure.

Figure 2: Scheme of the production process of fine grain isostatic graphite (Copyright SGL Carbon)

Recycling of EoL graphite from the solar value chain

After several months of operation at up to 1,500 °C, the CZ furnace needs to be dismantled and in part or fully replaced. As of today, End-of-life graphite parts are typically disposed of according to local regulations. In the ICARUS project, SGL Carbon is testing whether the EoL graphite received from the partners does have sufficient properties to be recycled. In a first step, they are using their comprehensive laboratory methods to analyze the EoL materials. After that, they will use their laboratory, pilot and production assets to test the processability of the EoL graphite and its respective impact on the virgin graphite produced.

ICARUS first results

Since material collection and graphite processing in particular are time-consuming processes, we expect to see results for the EoL processing of graphite at a later stage in this project.

Next steps

Next article will present the first results obtained during the ICARUS project.