Presentation of Life Cycle Assessment by bifa

Presentation of bifa and its role in ICARUS

As applications-orientated research, and development company, bifa Umweltinstitut GmbH provides a wide range of services covering every aspect of “technical environmental protection”. They include process engineering (mechanical engineering and apparatus construction), microbiological technologies and test methods, integrated operational environmental protection, sustainable waste management, system and process analysis, strategy development and policy advice, process technology engineering and chemical analysis.

In the ICARUS project bifa is responsible for work package 7 “Towards exploitation: process assessment: TEA, LCA, social acceptance”. bifa performs in the workpackage:

- Life Cycle Assessment, cost consideration, eco-efficiency analysis

- Circular economy system development

- Business case modelling

LCA: Life Cycle Assessment

Definition

In the LCA we refer to a system analysis method for integrated, media-wide recording and evaluation of environment-related matters in connection with products, processes and services. LCAs are characterized by the analyses of environmental influences in association with prior or subsequent life cycle stages. Inputs and withdrawals of raw materials and energy to and from environmental media, namely water, air and earth are included. Overall, a LCA can provide a comprehensive statement on the relevance to the environment of the systems investigated and are therefore optimally suited for environment-related comparison of various systems.

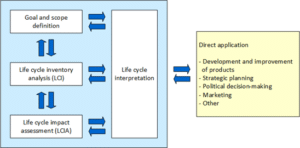

The LCA examination in this project is carried out under the norm specifications for the execution of life cycle assessments DIN EN ISO 14040 /14044, taken into account the Product Environmental Footprint Category Rules (PEFCR) for photovoltaic modules used in photovoltaic power systems for electricity generation from the European Union. Starting with the definition of goal and scope under the terms of the life cycle inventory analysis (LCI) analysis, all relevant parameters are recorded and summarized in the life cycle impact assessment (LCIA) regarding their environmental impact.

Schematic overview of the basic compilation of an LCA with fields of application [DIN 2006]

Life Cycle Inventory Assessment

The functional unit and the system boundaries are defined in the goal and scope definition. Drawing up a life cycle inventory analysis (LCI) includes the collection, deduction and preparation of specific process input and output data, system and process modelling and the calculation of the LCI. The LCIs are a basis for the life cycle inventory assessment (LCIA) and for evaluations. Under the framework of an LCIA the comprehensive results of the LCI are summarized and prepared for evaluation. The results of the LCI are aligned as far as possible in terms of (potential) environmental impacts and within these impact categories are calculated as accumulated values. The selection of the environmental impact categories observed within a specific LCIA is oriented to the current state of environment-related knowledge and to the project-specific cognitive interest. For this study the selected categories are those proposed by the Joint Research Centre of the European Commission – Institute for Environment and Sustainability and considered sufficiently robust. In detail these are:

- Climate change: Emissions of greenhouse gases change temperature and the climate for the worse. impacting indirectly also your health.

- Ozone depletion: Emissions damage the ozone layer leading to increased ultraviolet radiation resulting to skin cancer and damage to plants.

- Particulate matter: Emissions of tiny particles that lead to respiratory diseases and the so called “winter smog”.

- Ionizing radiation, human health: Radiation that increases risk of cancer.

- Photochemical ozone formation, human health: Emissions creating so called “summer smog” and respiratory diseases.

- Acidification: Emission of substance that lead to acid rain and poorer quality of air. water and soil.

- Eutrophication terrestrial: Too many nutrients in the environment. e.g. by over use of fertilisers in farming. upset the balance of nature.

- Eutrophication freshwater: Too many nutrients in freshwater. e.g. by the over use of fertilisers in farming and release of wastewater. upset the balance of nature. e.g. leading to algal blooms and killing fish.

- Eutrophication marine: Too many nutrients in marine water. e.g. by the over use of fertilisers in farming and release of wastewater. upset the balance of nature. e.g. leading to algal blooms in sea water.

- Land use: Use of land and soil endanger soil fertility as well as the survival of some species of animals and plants.

- Water use: The use of freshwater affects its availability for future uses.

- Resource use, metals and minerals: The use of minerals, metals and other resources in a product affects their availability for future uses.

- Resource use, energy carriers: The use fossil fuels affect their availability for future uses.

To compare the improvements and progress achieved in the project – such as the reduction of energy, media and material consumption – representative reference processes (mono-Si, multi-Si) must be set up for project monitoring. The associated state of the art data serves as reference points.

Modelling the impacts of the individual production chain sections

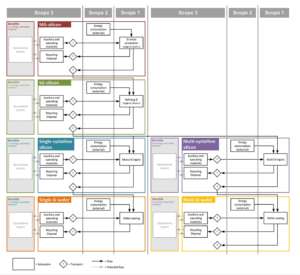

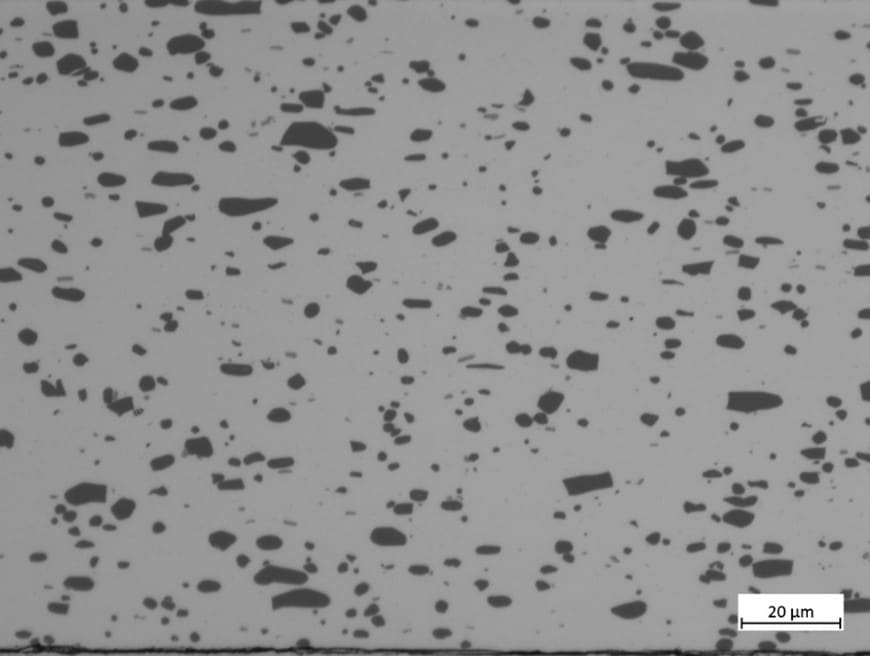

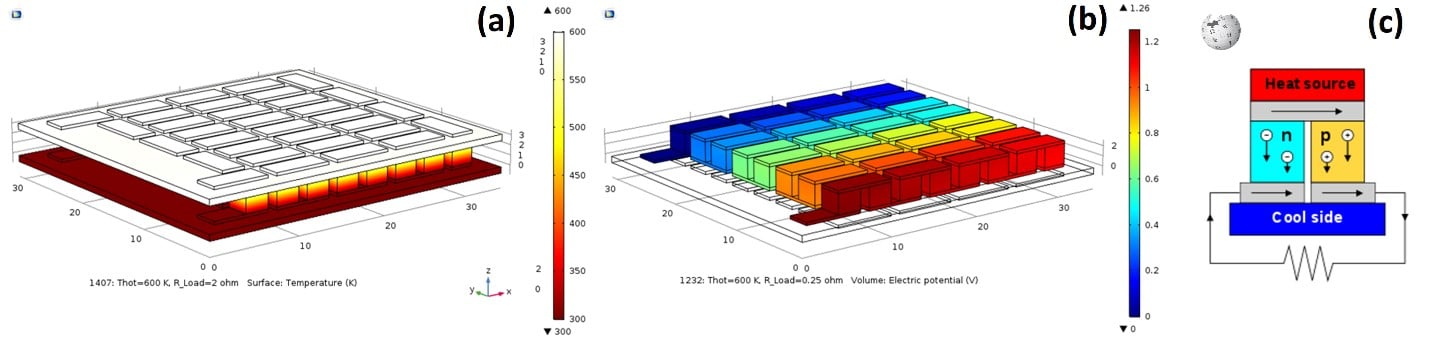

Based on the LCI data for the production chain: Si metal production (metallurgical grade silicon) –> refining Si (solar grade silicon) –> Si ingots (Czochralski single crystal and multi-crystalline ingot) –> wafer sawing (silicon wafer) matching with the project partners, material and energy flow models for benchmark processes were created. The model structure was built in a way that a sectoral evaluation of the results of the LCA is possible. On the one hand this makes it possible to identify the contributions of the individual production chain sections. On the other hand, the model structure enables to use the results to evaluate direct emissions from sources that are owned or controlled by the reporting entity, indirect emissions from consumption of purchased energy and all other indirect emissions.

Model structure of the material and energy flow model (LCA model)

ICARUS assessment : First results

The results of the LCIA of the benchmark processes at the current stage of processing are presented as examples based on two selected impact categories out of the thirteen presented above.

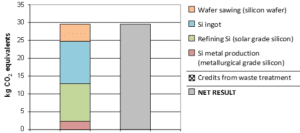

The net result of the impact category climate change of 1 m² mono-Si-wafer in the amount of total 30 kg CO2 equivalents is determined by the production of solar grade silicon and silicon ingot. 40 % and 36 % of total greenhouse gas emissions of the gross result (mainly carbon dioxide, methane, nitrous oxide) come from these two sections. With a share of 16 % emissions of wafer sawing play a minor role and emissions of the production of metallurgical grade silicon contribute less than 10 % to the gross result. There are no credits from waste treatment.

Benchmark (reference process): climate change of 1 m² mono-Si-wafer

The most important processes in the production chain sections to the gross result of the impact category climate are electricity supply and heat production for refining silicon and production of silicon ingots as well as the production of metallurgical grade silicon.

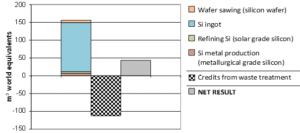

The net result of the impact category water use of 1 m² mono-Si-wafer in the amount of total 43.5 m³ world equivalents is determined by the production of silicon ingot. 88 % of the gross result on water use is required for this section. All other production chain sections contribute less than 10 % each. After allocation of credits from wastewater treatment the gross result is reduced by about 72 % to the net result.

Benchmark (reference process): water use of 1 m² mono-Si-wafer

The most important processes in the production chain sections to the gross result of the impact category water use are the production of silicon ingot with Czochralski process as well as electricity supply for production of metal-grade silicon, refining silicon and production of silicon ingots.

Next steps

As already mentioned, the benchmark results will later be compared with the improvements and advances made in the project for new processes/products, to determine the environmental advantages in addition to the technical feasibility. In the next bifa’s article, we will discuss the eco efficiency analysis envisioned during the ICARUS project.